We are LSF Constructors! Our services:

Production of LSF Structures Engineering Design & Calculations LSF Project Execution Construction

Recreational - Residential towns

A primary application of Light Steel Frame (LSF) structures is in the construction of large-scale residential townships and recreational compounds, such as those in coastal or mountainous regions.

Industrial buildings

Traditional industrial buildings present a major challenge for business owners: they require significant capital investment, and the extended construction timeline directly translates into lost production and profit. Every day spent building is a day your facility is not operating at capacity.

Governmental facilities

Governments worldwide undertake the construction of diverse public facilities to serve their citizens. For these projects, four factors are paramount: cost, speed, quality, and safety.

Apadana LSF

Apadana Construction Company commenced operations in 2010, engaging in construction projects across Iran (Mazandaran, Gilan, Azerbaijan, and Tehran provinces). The company aims to advance the development of residential, commercial, industrial, and governmental buildings. With a team of expert designers and engineers, Apadana possesses significant potential to execute large-scale projects domestically and internationally. This technical capability, combined with the founders’ risk-taking approach and commitment to localizing industry-specific technologies, positions Apadana as a pioneer in entering new markets and expanding services. Currently, the company focuses on modern Light Steel Frame (LSF) structures and operates its own galvanized LSF profile production facility, ensuring end-to-end quality control from manufacturing to execution.

Project Milestones

Company Objectives

Apadana maintains a long-term vision for modern construction, offering production, design, and construction services through a highly skilled team. Key objectives include:

- Implementing LSF structures to reduce building weight and enhance quality.

- Reducing project timelines to drive economic efficiency.

- Leveraging 15+ years of engineering expertise and global architectural innovations to advance the industry.

Services

Production of LSF Structures

Production of LSF Structures Light Steel Frames using premium, standardized materials.

Engineering Design & Calculations

Engineering Design & Calculations LSF-based structural design compliant with global standards (New Zealand methodology).

LSF Project Execution

LSF Project Execution Managed by experienced technical teams.

Construction of

Custom villas

Recreational/residential towns

Industrial buildings

Governmental facilities

Production of LSF Structures

Production of LSF Structures Light Steel Frames using premium, standardized materials.

Engineering Design & Calculations

Engineering Design & Calculations LSF-based structural design compliant with global standards (New Zealand methodology).

LSF Project Execution

LSF Project Execution Managed by experienced technical teams.

Construction of

Custom villas

Recreational/residential towns

Industrial buildings

Governmental facilities

Core Competencies of Apadana Construction Company

- High-Capacity Production: Monthly manufacturing capability exceeding 960 tons of LSF profiles (equivalent to 24,000+ square meters of building space).

- Proven Design Legacy: 18+ years of structural and architectural design expertise across 3,200+ buildings.

- End-to-End Project Delivery: Successful execution of 350+ turnkey construction projects from inception to completion.

- Integrated Specialist Teams: Deployment of seasoned professionals throughout all project phases::- Design - Structural & MEP installation - Construction

Apadana’s Competitive Advantages

- European machinery for LSF production with standard materials.

- Cutting-edge design aligned with global methodologies.

- Professional installation teams.

- Fast-track construction execution.

- Earthquake-resistant, energy-optimized buildings.

- Significant reduction in installation time, accelerating overall project completion.

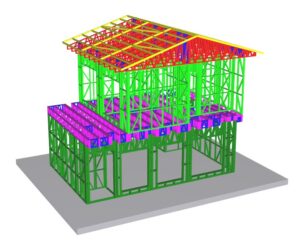

Benefits of LSF Construction

- Lightweight Steel Frame (LSF) refers to galvanized (hot-dip) cold-formed steel frames, offering:

- 30% lower construction costs due to lightweight structures.

- Applicable for buildings up to 5 stories.

- High thermal insulation (60% energy savings).

- Resistance to fire, earthquakes, and moisture.

- Demountable/re assemblable structures (with lightweight cladding).

- Easy maintenance of structures/MEP systems.

- High-safety load calculations (wind, snow, dead loads) using FrameCAD Detailer, FrameCAD Structure, and SAP2000.

- 80-120 year lifespan.

- Architectural space optimization.

- Rapid installation (50% faster project completion).

- Simplified electrical/mechanical system implementation.

- Design flexibility for facades (with compliant calculations).

- Eco-friendly, sustainable construction.

- Global certifications + local technical approvals.

- Near-zero structural defects.

portfolios

Frequently Asked Questions (FAQs)

How many stories can LSF structures support?

Typically up to 5 stories.

What is the weight of LSF buildings?

25–38 kg/m² (lighter than conventional buildings)

Describe an LSF building.

Comprises walls, roofs, and floors with LSF profiles as the core framework.

What is the LSF construction process?

- Steel sheets are shaped/joined into panels in the factory.

- Panels are transported to the site.

- Assembly on LSF-specific foundations.

- Cladding with OSB, gypsum, cement board, stone (façade), or ceramic (flooring).

What projects suit LSF?

Villas, residential/complexes, offices, industrial buildings, hotels, schools, restaurants.

Why are stairs built with hot-rolled steel instead of LSF?

Minimizes structural torsion/vibration by 90%

Minimum width for Swiss-style villas?

7.5 meters (optimal: 9 meters). Narrower widths reduce upper-floor space efficiency.